What are padel court walls made of?

High-strength safety glass: ensuring durability and safety

One of the most common materials for padel court walls is high-strength tempered glass. This glass is made by heating ordinary glass to near the softening point and then cooling it rapidly. It has extremely high impact resistance and thermal stability. Compared with ordinary glass, tempered glass is 4 to 5 times stronger and can withstand impacts such as player collisions and high-speed collisions of balls in padel games without breaking.

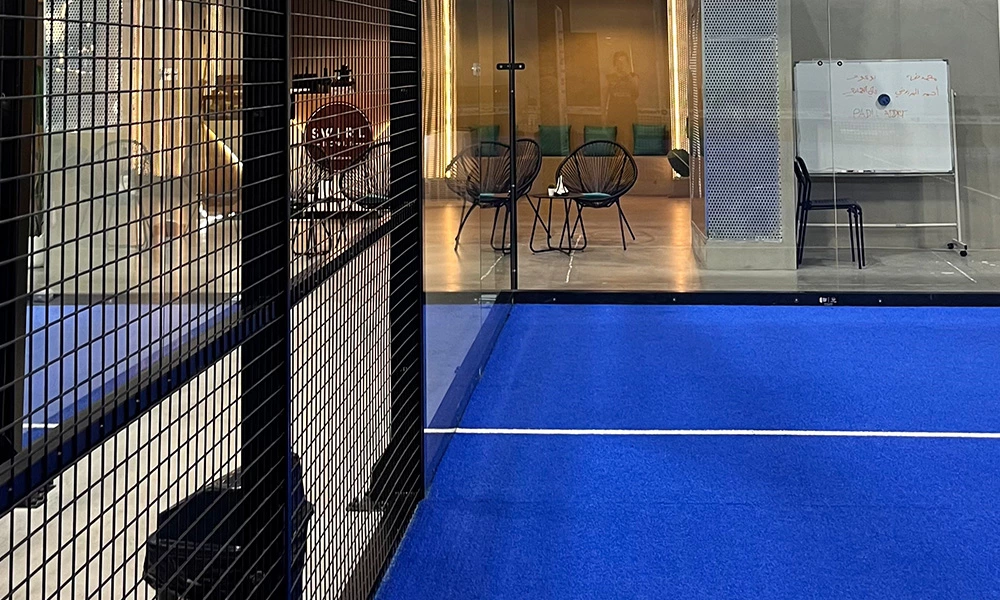

Transparent vision: improving the viewing experience

Padel sports emphasize viewing, and glass walls provide an unobstructed full-view experience. High-transparency tempered glass can clearly present the game screen, allowing the audience to clearly see every detail of the game even if they are sitting outside the venue. It is essential for hosting large-scale events or clubs to attract spectators.

Shatterproof design: ensuring user safety

Even if the glass is damaged in extreme cases, high-strength tempered glass will break into uniform blunt-angle small particles instead of sharp fragments, greatly reducing the risk of cuts. This feature makes it the preferred material in high-frequency sports scenes.

Glass specifications and thickness standards

The thickness of glass commonly used in padel courts is 10 mm to 12 mm, which varies slightly depending on whether the venue is used for competition, climate environment and bearing capacity requirements. International competition standard venues usually use 12 mm thick tempered glass to ensure stability, sound insulation and long service life.

Strong weather resistance: suitable for indoor and outdoor use

Padel court glass also has good weather resistance. Whether it is high temperature, cold, or humid environment, tempered glass can maintain stable shape, no discoloration, and not easy to age, so it is widely used in outdoor court projects.

Customized processing: meet diverse design needs

Tempered glass can also be punched, edged, and silk-screened according to project requirements. Explosion-proof film treatment to achieve higher structural compatibility and aesthetics. For example, silk-screen processing can print club logos, sponsor patterns, etc. on the glass to enhance brand recognition.